CFO Mindset and Strategies

How Corporates Can Overcome Roadblocks to Last-Mile Supply Chain Visibility

In global boardrooms, supply chain visibility is now as urgent a priority as revenue growth. Yet in the final stretch—the “last mile”, most corporates still operate with one eye closed. Deliveries that vanish into information black holes, mismatched invoices, and unnoticed supplier failures are symptoms of this persistent challenge. For companies under pressure to deliver faster, leaner, and safer; the last mile is a strategic imperative.

A McKinsey study found that organizations with end-to-end visibility cut disruption impacts by up to 50%. And yet, nearly half of logistics leaders admit they still lack reliable tools. If real-time tracking is the standard for consumer food delivery apps, why is it elusive for multi-million-dollar shipments? The answer lies in structural, financial, and cultural barriers that corporates must dismantle.

The Roadblocks to Seeing Clearly

High Tech Costs: IoT devices, GPS trackers, and control towers promise precision, but their price tags keep many companies hesitant. For industries with 3–5% margins, scaling beyond pilots feels like a leap into the unknown.

Unclear ROI: The payoff of visibility is usually measured in problems avoided. CFOs often struggle to quantify avoided losses, making ROI unclear.

Unreliable Data: When product codes vary across partners or shipment updates are days old, dashboards lose reliability. Tive’s 2024 State of Visibility report found that 60% of companies only discovered shipment damage after delivery, compounding losses and customer dissatisfaction.

Incompatible Legacy Systems: Many supply chains are stitched from decades-old ERPs, third-party platforms, and spreadsheets. Integrating them is like assembling a complex puzzle whose pieces come from different sets.

People Problems: Even when the tech works, reluctance to change entrenched processes or share data across silos can stall progress before it starts.

Defogging the Supply Chain

So how can corporates move from excuses to action?

Start Small, Prove Big: Focusing on one fragile link: a high-value lane, a problematic supplier, or a time-critical delivery, helps show quick wins. Preventing just one disruption builds a strong case.

Clean the Data Before Using It: Standardizing codes, assigning ownership, and setting partner agreements may be less glamorous than new tools, but they are critical to reliable visibility.

Layer in Smart Technology: IoT sensors and GPS trackers now monitor not just location but temperature, shock, and tampering. Paired with AI, they shift visibility from reactive to predictive, enabling timely intervention. Advanced tools like digital twins now allow corporates to simulate the entire supply chain virtually, predicting disruptions, optimizing routes, and aligning operational, financial, and ESG outcomes in real time. Control towers centralize this data, offering a real-time operational hub that alerts teams to risks and ensures coordinated responses across the last mile.

Build a Collaborative Culture: Visibility depends on collaboration. Corporates that bring suppliers, partners, and internal teams together around shared dashboards unlock far greater value than those viewing it as a technology project alone.

Tie Visibility to Finance: Real-time tracking of shipments and invoices reduces disputes, strengthens working capital, and builds lender confidence. Supply Chain Finance (SCF) works best when financiers see proof of delivery, while Credit Risk Assessment sharpens with performance data.

When Visibility Meets Finance

A shipment delay upsets customers and could postpone invoices, strain supplier cash flow, and heighten credit risk. Real-time updates reassure financiers, keep suppliers paid on time, and give customers reliability.

New-age dashboards from Vayana now provide corporates with a single view of their payables, receivables, financing programs, Lenders (FIs), and counterparties. By unifying these flows, they extend supply chain visibility into finance itself, helping treasury teams track obligations, reconcile payments faster, and turn liquidity management into a competitive edge.

Visibility also streamlines validation and improves payment predictability. Transparent cycles encourage supplier participation in Supply Chain Finance, while buyers gain competitive pricing and stronger relationships. For lenders, insight into milestones and performance reduces uncertainty, enabling financing to reach deeper into the chain.

The good news, corporates are realising this. In a 2025 Maersk survey, 86% of the corporate key decision makers surveyed cited supply chain visibility as the top logistics trend concerning their company.

The ESG Imperative

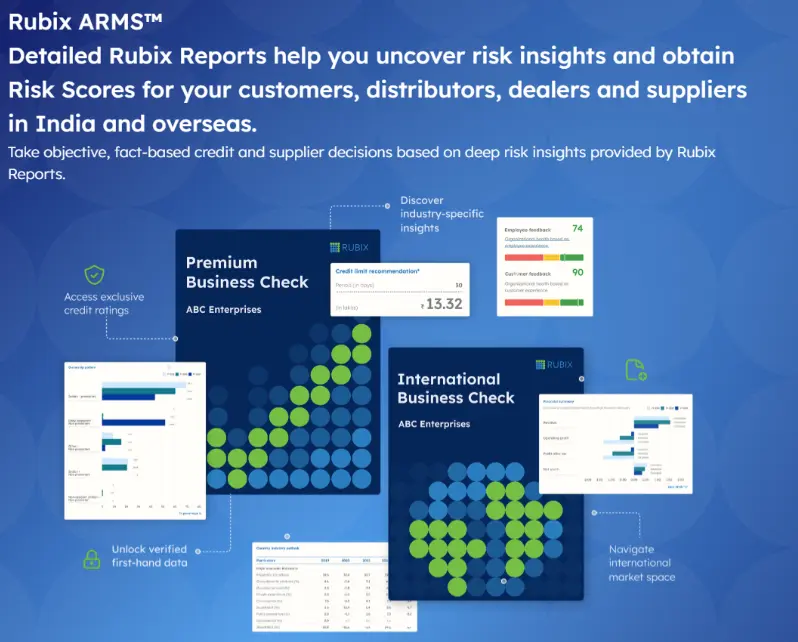

Visibility goes beyond finance; it underpins ESG compliance. Regulators and investors demand proof of emission cuts, ethical sourcing, and responsible practices. Without last-mile visibility, corporates risk penalties and reputational harm. With it, they can disclose ESG metrics confidently. Rubix ESG supports measurement, reporting, and transparency across stakeholders.

From Blind Spots to Strategic Advantage

Last-mile visibility is not optional anymore. It safeguards customer trust, strengthens liquidity, supports ESG compliance, and turns potential disruptions into opportunities. By combining clean data, smart technology, and cross-functional collaboration, corporates can shift from reactive problem-solving to strategic resilience.

The payoff is tangible: fewer shipment disputes, smoother cash flows, more effective supply chain finance participation, and stronger supplier relationships. In short, visibility transforms the last mile from a risk-filled blind spot into a source of competitive advantage.