Supply Chain Finance

Supply Chain Finance - An Imperative for FMCG Companies of India

Imagine it is the end of June. The monsoon has arrived late, and Madhya Pradesh is battling both soaring humidity and patchy rainfall. At a warehouse outside Indore, water pools in the loading bay as a refrigerated truck waits to be stocked with crates of mango drinks and flavored yogurts for distribution across the central belt.

But there’s a problem.

The vendor who supplies the PET bottles hasn’t delivered. He’s been struggling with rising polymer prices and hasn’t received payment for the last three consignments. His bank turned down his working capital loan request. So, for now, he’s paused all orders.

At first glance, this looks like a minor disruption. But the ripple spreads quickly.

The FMCG brand’s sales team calls in frustrated. Ads have already gone live. Retailers are running empty shelves. Distributors in Raipur and Bhopal are pushing back on targets. Cold chain logistics, booked in advance, are sitting idle.

The CFO is pulled into an emergency meeting. Finance wasn’t even directly involved with this vendor. But now, marketing, sales, procurement, and logistics are all firefighting a problem that began with a single unpaid invoice.

This isn’t a fictional story. It’s a composite of real disruptions we’ve seen unfold across Indian supply chains. It’s a reminder that Supply Chain Finance has evolved from a niche solution to a foundational pillar of resilient operations.

FMCG Supply Chains Aren’t Just Fast. They’re Fragile.

Fast-moving consumer goods are, by definition, fast. But paradoxically, the cash that fuels them moves slowly. Operating on razor-thin margins, high SKU churn, and just-in-time inventory, the FMCG sector is highly vulnerable to liquidity shocks. Payment delays of 60–90 days are standard practice, even among well-known corporates. But it’s the MSME suppliers who take the hit.

India’s MSME credit gap stands at ₹25 trillion (USD 330 billion). Many suppliers rely on informal lending at exorbitant interest rates, simply to stay afloat.

And here’s the paradox: most large FMCG brands aren’t delaying payments out of malice, but due to ERP mismatches, internal approval cycles, or channel complexities. The working capital burden simply cascades down the supply chain.

Now imagine this during Diwali season. Or during a product push backed by an IPL ad campaign. One upstream payment delay can choke ₹100 crore in downstream sales.

Why This Matters in 2025 ?

India’s FMCG sector is expected to touch USD 220 billion by 2025, as per Invest India. But rapid growth brings with it heightened risk. Liquidity bottlenecks, delayed payments, and vendor fragility are becoming systemic concerns.

A key reason? Most large FMCG companies rely heavily on MSMEs to manufacture, package, and transport their products. These enterprises are the invisible backbone of the supply chain—from raw material conversion to last-mile logistics. When they are starved of working capital, the entire ecosystem suffers.

As The Times of India recently noted, India’s MSMEs are standing at a crucial inflection point, one defined by the ability to scale, digitize, and build resilience. Yet, most remain outside the fold of India’s digital revolution.

A report in Policy Circle echoes the urgency: while SMEs contribute 30% to GDP and 45% of manufacturing output, their digital adoption remains limited restricting their ability to plug into formal finance ecosystems like SCF.

If left unaddressed, these gaps could derail India’s ambitions of becoming a $5 trillion economy.

SCF Is Not a Treasury Product. It’s a Resilience Strategy.

Supply Chain Finance enables large buyers to unlock liquidity across their vendor base, without disrupting their own cash cycles. MSME suppliers are paid early by financiers; the buyer repays later, on their original due date.

For CFOs, SCF becomes a strategic lever to:

- Ensure continuity in peak seasons

- Mitigate operational risk

- Improve working capital

- Strengthen supplier relationships

Let’s break down what this requires from the modern CFO.

1. Reframe SCF as a Liquidity Strategy, not a Procurement Tool

SCF is often parked under procurement or treasury. But to create impact, it must be owned and led by finance.

Action Points:

- Set coverage goals: % of vendors onboarded, % of invoice volume financed

- Monitor SCF adoption as a risk mitigation KPI

- Include SCF targets in supplier reviews and QBRs

2. Prioritize High-Risk, High-Impact Suppliers

Not all suppliers are created equal. CFOs could partner with procurement to overlay financial vulnerability with supply chain criticality.

Prioritize onboarding:

- MSMEs supplying high-turnover SKUs (e.g., packaging, logistics, perishables)

- Vendors in volatile input markets (e.g., dairy, oils, polymers)

- Women-led and rural suppliers with limited credit access

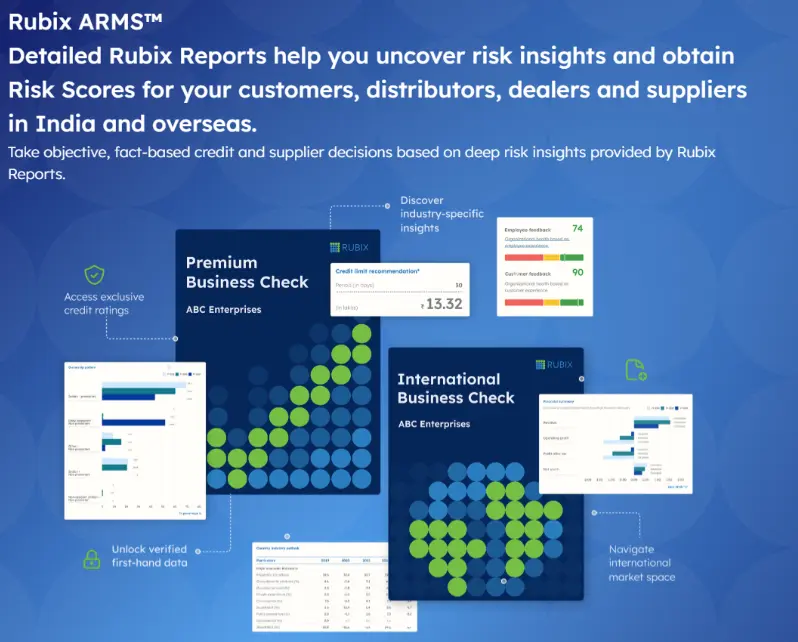

Platforms like Rubix EWS can help by proactively tracking financial health, compliance status, and media mentions of suppliers—flagging risks before they escalate. This enables CFOs to make informed onboarding and financing decisions for high-impact, high-risk vendors.

3. Turn SCF into a Finance Control Centre

Modern SCF isn’t just about financing invoices; it’s about empowering CFOs with complete financial visibility and control. By aligning SCF with budgeting cycles and tracking critical metrics like bank-wise exposure, utilization trends, and credit limits, finance leaders can:

- Forecast working capital more accurately

- Reduce dependency risk across FIs

- Take early action to avoid disruptions during peak seasons

Platforms like Vayana Vantage bring all these insights together, turning fragmented data into clear, actionable intelligence.

4. Champion Flexible, Frictionless Onboarding

One reason many SCF programs fail? Lack of supplier adoption.

CFOs must insist on:

- Multi-financer platforms for competitive rates

- Embedded finance tools that integrate with billing software

With MSMEs at the core, Vayana’s SCF platform enable smaller suppliers to tap into formal credit when they need it most.

What CFOs Stand to Gain ?

Done right, SCF becomes a win-win. Here’s how:

- Buyers can free up internal cash while improving liquidity at the supplier level.

- Early payments often unlock discounts that offset SCF costs and improve EBITDA.

- Liquidity-supportive buyers become preferred customers—translating into better vendor terms and loyalty.

- By linking SCF rates to ESG performance (e.g., lower emissions, women ownership), companies can create Green SCF programs that align with sustainability goals.

- Whether it’s climate shocks, geopolitical shifts, or sudden demand surges, SCF acts as a financial shock absorber.

Supply Chain Finance is emerging as the CFO’s stealth lever; turning fragile vendor networks into resilient growth engines, while aligning liquidity, sustainability, and competitive edge.